TRANSPORT

Minniti autotrasporti Mortara Tankcleaning

Minniti Autotrasporti is your trusted logistics partner for the transport of chemical and foodstuff liquids in tank-containers. We are specialized in the transport of ADR liquid products and registered in the National Register of Environmental Managers for the collection and transport of special hazardous waste.

The operational headquarters is strategically located in Mortara, in the Italian region of chemistry: Lombardy. The distance from the Milan traffic and the immediate proximity to the Mortara intermodal railway terminal, connected with the main logistic hubs of Northern Europe (Rotterdam, Gent and Krefeld), allows us to offer to our customers a timely, efficient and environmentally sustainable service, benefiting of the advantages of intermodal transport.

Our action range includes mainly the metropolitan area of Turin, Novara, Milan, Bergamo and the port area of Genoa, Savona and Vado Ligure.

Minniti autotrasporti Mortara Tankcleaning

Drivers and vehicles are all suitable and authorized for the transport of ADR goods. The ADR classes carried are:

- Class 2 Gases (refrigerant, flammable and cryogenic)

- Class 3 Flammable liquid

- Class 5 Oxidizing substances and Organic peroxides

- Class 6 Toxic and Infectious substances

- Class 8 Corrosive substances

- Class 9 Miscellaneous dangerous substances and article

Our vehicle fleet includes:

- TRUCKS euro 6 equipped with the most advanced safety devices, GPS and vane compressors for the unload of viscous products (suitable both for the chemicals and for foodstuffs);

- CHASSIS of all sizes, equipped with hose and hose box for chemicals and foodstuffs: 20 feet for isotank, 25 feet specific for swapbody tank, 30 feet, 40 and 45 feet.

Minniti Autotrasporti is a company that boasts of a long experience specialized in offering integrated logistics services for the transport of liquids in tanks. Over the years the innovative business strategy and the trust of our customers has allowed us to increase our skills by becoming a strategic partner of success.

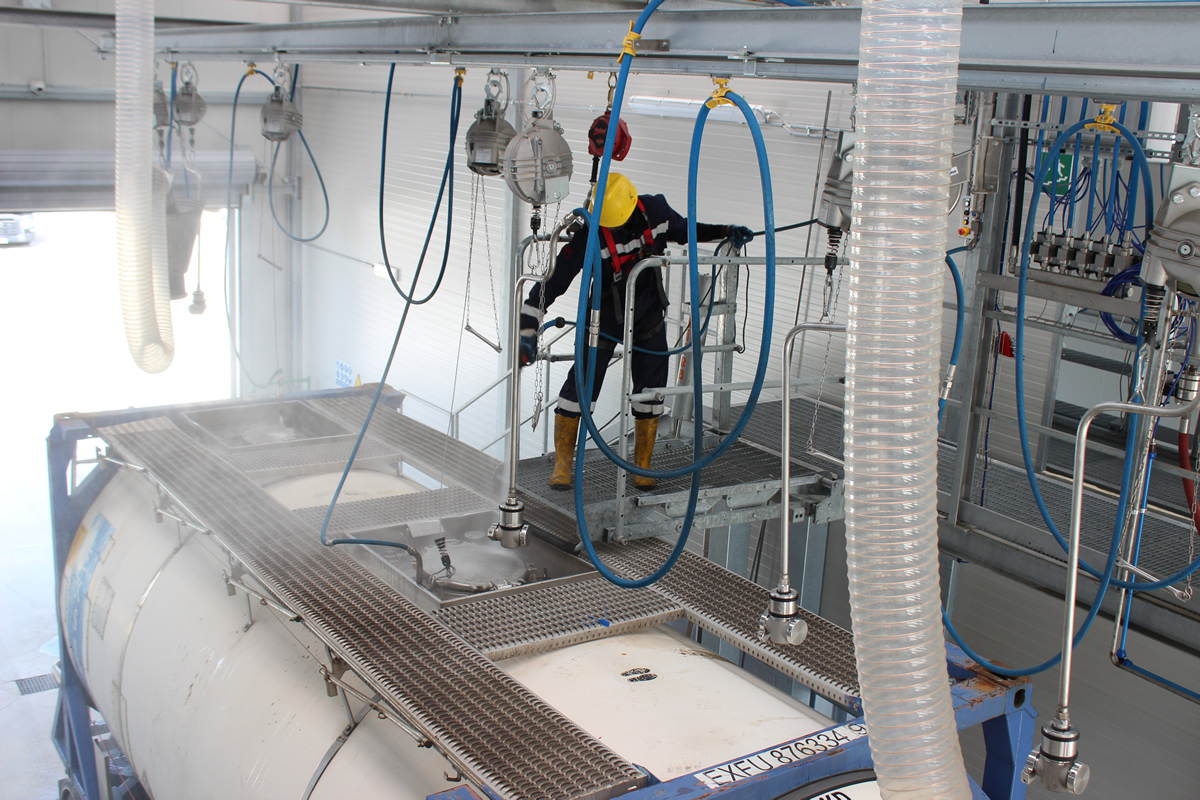

TANK CLEANING

Minniti Tank Cleaning takes care of the cleaning of road-tanks and tank-containers containing both chemical and foodstuff products. The ATEX certified and newly manufactured cleaning plant is equipped with the most advanced technologies available on the market. It’s equipped with 3 cleaning bays with 17 high-pressure cleaning heads (110 bar):

- 2 bays are dedicated to cleaning tanks containing chemical products

- 1 bay, separated from the chemical zone, is dedicated to cleaning and sanitisation of tanks containing foodstuff products

The management of the PRODUCTIVE CYCLE is entrusted to a software that allows

- the control and the setting of water temperature and working pressure

- the control and the setting of detergent percentage

- the traceability of the cleaning cycle adopted

- the reduction of intervention times

- the maintenance scheduling

The cleaning procedures are created ad hoc for each product to be cleaned by programming the intervention times, the water temperature, the pressure and the most suitable detergent. We offer the possibility of customizing the cleaning process according to the explicit requirements of the customer, detailing times and the intervention characteristics of each single phase.

In synergy with the container storage service the staff of Minniti Tank Cleaning carries out unaccompanied cleanings for tank-containers and ordinary maintenance and repair in the One-Stop-Shop perspective. It is also possible to use the shuttle service to and from Mortara terminal in order to reset the wasted time for the cleaning of your tanks.

The washing plant is part of the European EFTCO certification circuit and can issue the European ECD washing certificate.

Other complementary services

- internal drying of tanks with filtered hot air

- specific internal drying of silos with filtered hot

- sealing of the tank to guarantee its correct cleaning

- deodorization

- sanitisation

- pH test

- pressure test

- vacuum test

- high pressure cleaning head for isotank from 170 l/min at 110 bar

- external cleaning of tanks

Services for drivers

- showers

- WC

- refreshment point

- mail service

- receipt documents

- credit card payment

Minniti autotrasporti Mortara Tankcleaning

1

READY TO LOAD IN NORTHERN EUROPE

CLEANING ORDER

Minniti DEPOT

Minniti TANK CLEANING

MORTARA TERMINAL

Gent

Rotterdam

Krefeld

2

READY TO LOAD IN ITALY

CLEANING ORDER

Gent

Rotterdam

Krefeld

MORTARA TERMINAL

Minniti TANK CLEANING

FACTORY

Minniti DEPOT

PRODUCTS HEATING

Some products are temperature sensitive. During the logistic process, it happens that these products need be heated and brought back to the optimal temperature before being delivered to the end customer. In this regard we offer to our customers the possibility of heating tanks by using steam, hot water and electricity.

The service is guaranteed 24/7 without interruption.

Steam

We have an efficient steam heating system with the possibility of modulating the pressure based on the characteristics of the product and the customer’s requests. Each of the 10 heating points, equipped with condense recovery, is independent of the others and allows to produce steam up to 10 bar pressure and 180°C.

Minniti autotrasporti Mortara Tankcleaning

Hot water

For the most sensitive products it is possible to use hot water adjustable up to a temperature of 80°C.

Electricity

Some vehicles are equipped with their own heating system powered by electricity. In our heating station, 4 slots are available for the supply of electricity needed for the vehicle system.

- internal temperature probe control

- tank container shunting from the railway terminal to the heating station

PRODUCTS HEATING

Gent

Rotterdam

Krefeld

MORTARA TERMINAL

SHUNTING

Minniti HEATING

FACTORY

CONTAINER DEPOT

We are equipped with two Reachstacker with which we can handle tank-containers, containers and swap bodies of all sizes (20′- 30 ’- 40’), up to a maximum capacity of 45 tons. We allow our customers to store full and empty containers in an area of 25,000 square meters entirely fenced, video-monitored and alarmed with remote control.

In synergy with the tank cleaning service our expert staff perform maintenance and repair according to the highest quality standards, respecting the needs of our customers in the maintenance of their tanks.

- change of malids gaskets and valves seals

- catwalks repair

- pressure tests both for tank and valves

- vacuum test

- pressure test of the heating coils

- revision and replacement of bottom / butterfly / safety valves

If necessary, repairs can be inspected and certified by independent certification Companies.

ONE STOP SHOP

CLEANING

MAINTENANCE AND REPAIR

DEPOT

SAFETY, QUALITY AND ENVIRONMENT

Minniti Autotrasporti s.r.l undertakes to guarantee high standards of safety during the daily activities of operators and drivers and respect for the environment, paying particular attention to the search for an excellent level of water treatment and the reduction of emissions into the atmosphere. The cleaning procedures and the subsequent treatment of the waste water are aimed at minimizing the water sent to the treatment, favoring the recycling of potentially polluting materials.

The water purification system is made of:

- predecanting tanks

- oil separation tanks

- chemical-physical treatment plant with controlled pH

- S.B.R biological treatment plant with pH, Redox, conductivity and temperature control devices

- monitoring of parameters at the unload

This system guarantees high standards of unloaded water, minimizing the environmental impact. The purified water is unloaded into the public sewer in accordance with the limits established by law. The Management is also committed to disclose the Quality and Environment Policy towards all staff and their understanding at all levels.

CONTACTS

MINNITI AUTOTRASPORTI s.r.l

Registered Office: Via de Medici 27 – 28043 Bellinzago Novarese (NO)

Operating Office: Via Albert Eistein 1 – 27036 Mortara (PV)

PEC: minnitisrl@pec.it